Spiral Manufacturing

Spiral Machining and CNC Machining

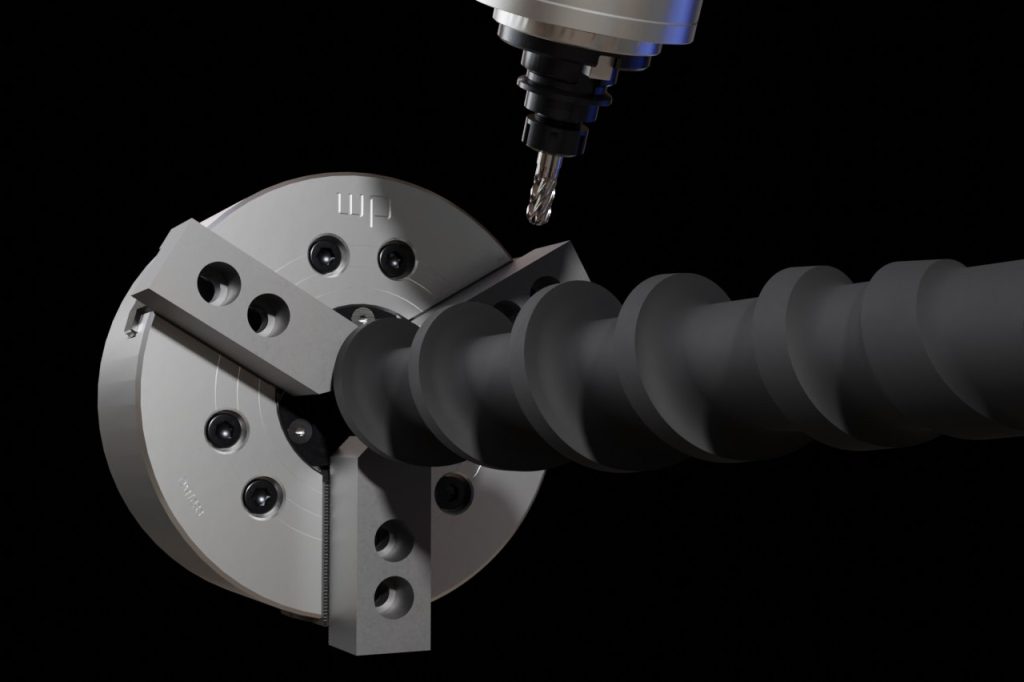

Machining plays a critical role, especially in the production of industrial components. Spiral manufacturing is one of these processes and has a wide range of applications in various sectors. As Doğa Makina, we produce high quality and durable augers by performing high precision CNC machining with our Mazak Integrex machines.

High Precision Manufacturing with Mazak Integrex Machine Tools

Mazak Integrex machines offer superior performance and precision in the production of screws. Thanks to their multi-axis machining capabilities, these machines enable even components with complex geometry to be machined easily. CNC technology guarantees consistency and quality at every production stage, while increasing the efficiency of the production process.

Advantages of Machining

Machining enables components such as screws to achieve the desired tolerances and surface quality. This process makes it possible to remove material in a controlled manner and produce high-precision parts. Our CNC machines machine even the most complex designs with high accuracy, which reduces production costs and shortens lead times.

Auger and Feeding Screws "FEEDSCREW" Areas of Use

Augers and feed screws(feedscrew) is of vital importance in many industrial applications. On conveyor belts, it ensures that materials are transported in an organised and controlled manner. It also plays a critical role in filling lines, packaging machines, agricultural machinery, chemical industry, food processing plants and various automation systems. Thanks to their durability and performance, our augers help industrial processes to run smoothly.

Why Doğa Makina?

As Doğa Makina, we offer customer-oriented solutions and aim to increase the efficiency of your production processes. With our Mazak Integrex machines and our expert team, we produce augers and feed screws tailored to your needs. We are proud to offer you the best service with our high quality standards and technological competences.

Contact us for your spiral manufacturing and other machining needs. With our experience in the sector and innovative solutions, we are with you at every stage of your production processes.