What is an Extrusion Mould?

Extrusion die is a special type of die used for shaping plastics, aluminium and other metals. This method allows the material to be formed into a certain shape, creating long and uniform profiles.

Usage Areas of Extrusion Moulds

The extrusion method is commonly used in the following industries:

- Aluminium Industry: Windows, door profiles, building facades.

- Plastic Industry: PVC pipes, cable ducts, plastic profiles.

- Automotive Industry: Vehicle cladding, trim profiles.

- Packaging Sector: Film and sheet production.

Extrusion Mould Design

Extrusion mould design is determined according to the properties of the material to be processed and the final product shape. Correct design is very important for obtaining quality products. The design process consists of the following stages:

- Material Selection: Plastic, aluminium, copper or other metals.

- Profile Design: Determining the shape of the final product.

- Flow Analysis: Using simulation to ensure the regular flow of material in the mould.

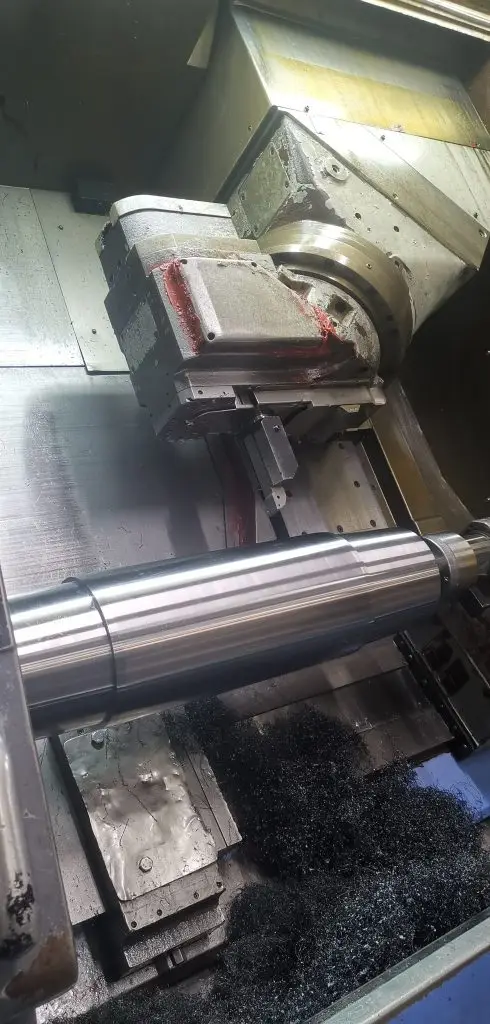

- Mould Production: Precision machined moulds with CNC machines.

Extrusion Mould Production Process

The production process of extrusion moulds requires very precise and detailed planning:

- Raw Material Selection: Hardened steel is usually used to make the mould durable.

- Mould Processing with CNC: Precision mould production with computer aided machining.

- Surface Finishing: Hard coating and polishing processes are applied to prevent mould wear.

- Testing and Revision: Quality control is ensured by sample production.

Advantages of Extrusion Moulds

- High Efficiency: It is a fast and economical method in mass production.

- Precise Measurements: Minimum margin of error thanks to CNC supported production.

- Wide Range of Materials: Compatible with different materials such as plastic, aluminium and steel.

- Low Wastage Rate: Minimises material waste.

Conclusion

Extrusion moulds are precision production methods that play an important role in industrial production. Long-lasting and efficient moulds can be obtained with the correct design and the use of quality materials. More precise and cost-effective solutions can be offered with CNC-assisted machining techniques.

Keywords: extrusion die, extrusion die design, CNC machining, aluminium extrusion, plastic extrusion, extrusion die production, extrusion method.