PRODUCTION | Manufacturing

Precision Solutions in CNC Part Manufacturing

Precision CNC Part Manufacturing: From Hydraulic Chucks to Flanges

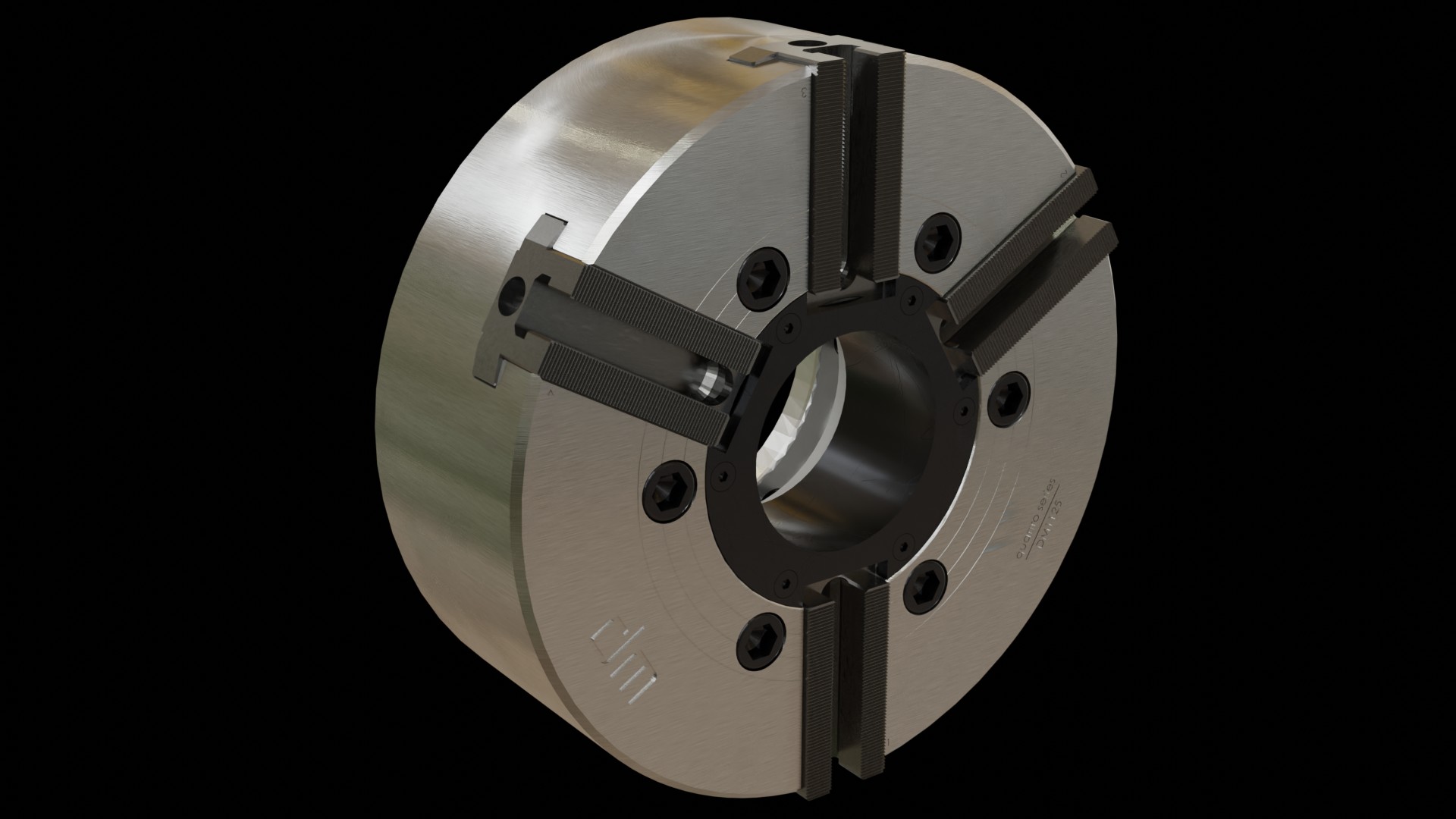

Our company specialises in precision machining projects for CNC parts. We provide high quality service in the production of hydraulic chuck, pin, bushing, flange, ring, shaft, shaft, gear, bearing, bolt and similar parts machined on CNC machines.

With our modern CNC machines and experienced team, we offer our customers solutions to meet the most complex and precise demands. As a reliable partner in the industrial industry, we are at your side for all your machining needs.

Our Projects

Cnc Powerchuck

2 feet

Hydraulic Mirror

3 feet

Hydraulic Mirror

4 feet

Hydraulic Mirror

15-24 inches

Hydraulic Mirror

R&D Projects

R&D Projects

3+2 Jaw Powerchuck

Powerchucks constitute a type of CNC lathe chucks and provide a high level of convenience in connecting the part to be processed by fixing it to the machine tools. Currently in Turkey, including our company; two-jaw, three-jaw and four-jaw powerchucks are produced. The use of these chucks differs according to the type of part. While angular parts such as square or rectangular parts are processed with the 2-jaw powerchuck currently being produced, round diameter parts are processed with 3-jaw powerchuck. Due to this situation, many problems are encountered during production. During the machining of parts with different geometries, powerchuck need to be replaced. This causes the production speed to extend for half a day even for a 1-day process. In a product that requires the use of two-jaw and three-jaw powerchucks, chuck replacement causes an increase in the transition times between operations.

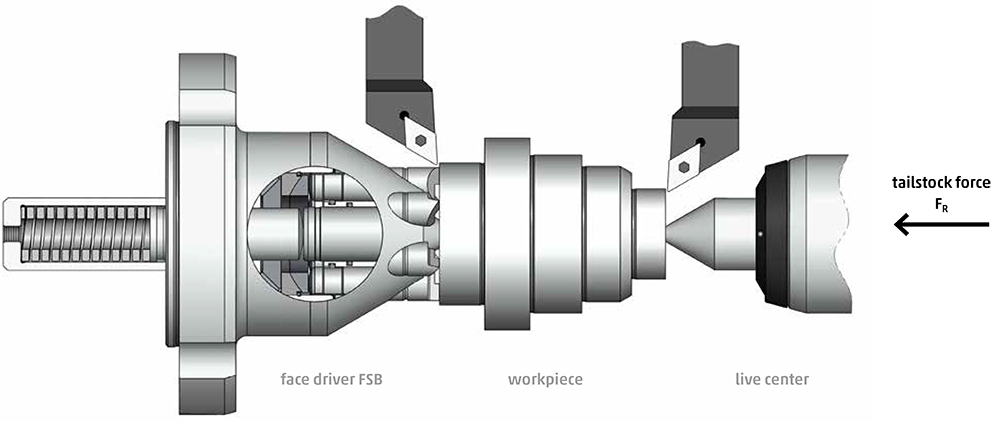

Hydraulic Nail Tailstock

It is aimed to make the prototype of "Hydraulic Nail Tailstock" which will provide the opportunity to hold even on prone surfaces between tailstock and nail, provide easier processing in products that cannot be cut straight, and obtain a smooth surface by reducing vibration and vibration.

- With max. 30 bar pressure resistance, the nails will sink into the part up to 1-2 mm, and the runout in the part will be ensured to be within the tolerance range of +0.01 to -0.01 mm.

- With hydraulic oil minimum vibration and will provide savings in the use of bits with its strength structure.

- On face surfaces that are not cut straight Due to the movable oil pins, it will apply even pressure to the surface and will create process capability on both curved and flat surfaces.

- The entire surface of the workpiece in a single installation squeezing between centres for processing will optimise the production flow and reduce production costs.

- Workpiece maintaining the centre line the actual working accuracy of the workpiece can be achieved.

Cnc Precision Machining Projects

Current Cnc Part Machining Examples

Contract mass production is preferred for your business to place large-scale production orders to another manufacturer instead of its own production facilities for the pins, bushings, flanges, rings, shafts, shafts, shafts, gears, bearings, bolts that your business needs and to reduce costs, increase production capacity and outsource processes that require expertise. Our company has the ability to produce large quantities of products with high quality and precision, thus enabling your company to respond quickly and efficiently to market demands.