ABOUT US

About Us

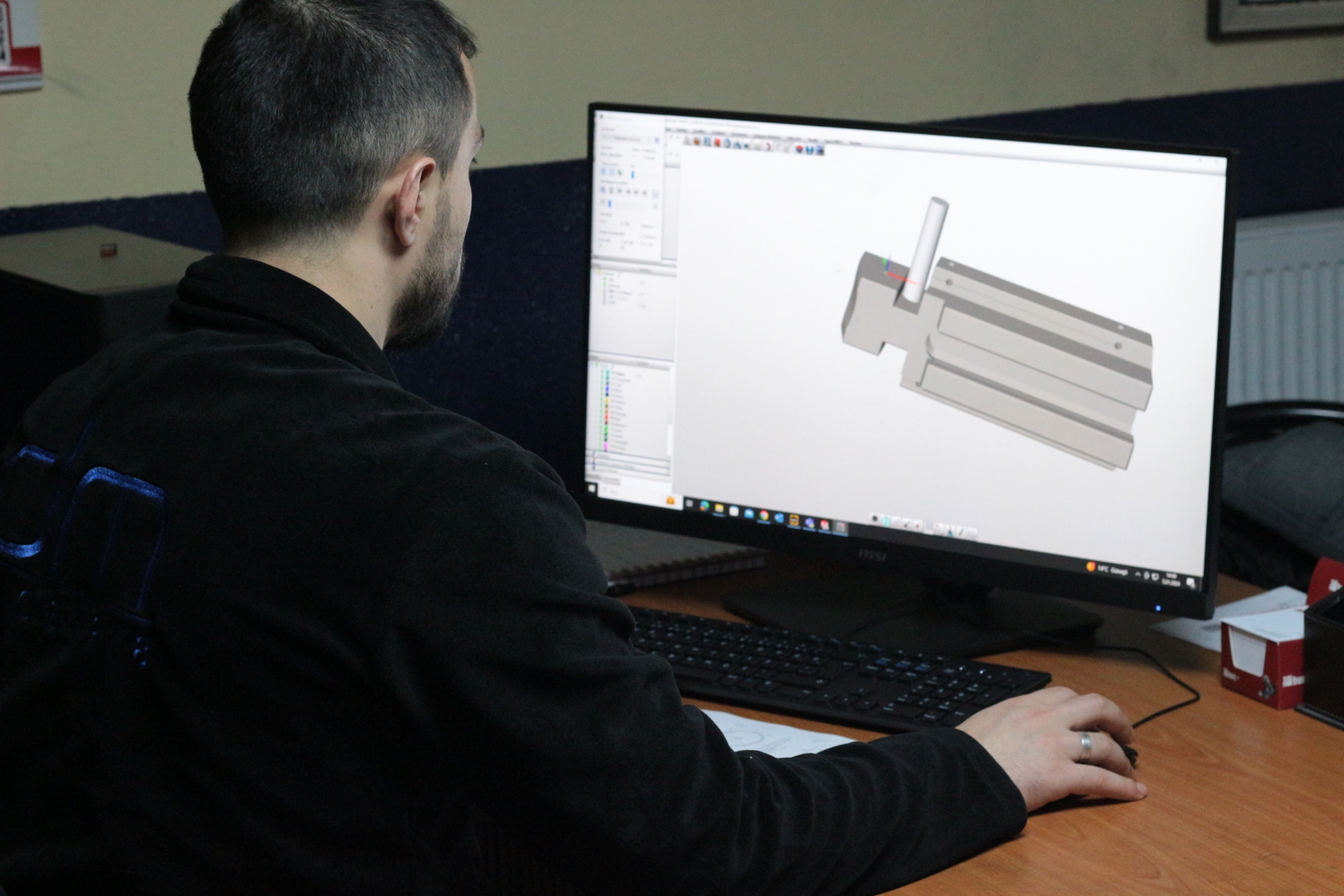

Since 1978, we have been providing services to industrial sectors

Doga Makina Istanbul machining who made is one of the first companies. Since 1978, it has been carrying out production activities at the highest quality standards. With years of experience and experience, it has adopted the principle of achieving high quality standards even in the most sensitive works.

Our company, which operates in various sectors, has also been active in the Iron and Steel, Construction, Energy, Automotive, Defence Industry sectors. With its professional and specialised staff, it works as contract manufacturing and mass production as sub-industry to leading companies in their sectors.

QUALITY POLICY

To keep customer satisfaction at the highest level by continuously increasing Reducing costs by increasing efficiency To use error prevention techniques predominantly in the management of products, processes, plants, equipment, systems and resources To continuously improve our products, processes, facilities, equipment, systems and resources in accordance with the quality system rules

OUR VALUES

Occupational health and safety Giving importance to saving Customer orientated work Considering the accumulation of trained, experienced and participatory labour force as the most important asset Based on continuous improvement, innovation and positive change Protecting the environment Contributing to society and fairly valuing people in all our activities Considering the accumulation of trained, experienced and participatory labour force as the most important asset

Our Environmental Policy

The environmental policy for our company includes measures such as reducing the amount of waste, promoting recycling and improving energy efficiency. This policy strengthens the company's sustainability and competitive advantage while minimising environmental impacts.

A long journey from 1978 to today

HISTORY

1978

DOĞA CUTTING TOOLS KOLL. It was established to manufacture special cutting tools under the name of ŞTİ.

1983

Started to serve the automotive sub-industry (sub-industry to Tofaş group)

1988

Our company has moved to its own factory building built in Pendik - Kurtköy.

1989

CNC horizontal lathe was purchased as one of the first companies in Turkey.

2002

It started to serve the main casting sector. ISO 9001-2000 Quality Certificate

2006

Our company continues its service with the title of DOĞA MAKİNA İTH. VE İHR. LTD. ŞTİ in order to work for export.

2011

As of January, DOĞRUYOL MAKİNA İTH. VE İHR. LTD. ŞTİ was established in order to carry out the sales and marketing activities of our company.

2015

With the cooperation of istanbul Ulaşım - Doğa Makina, the turning of the metro wheels within the scope of the localisation of the istanbul metro was carried out in our company.

2018

Cnc hydraulic chuck manufacturing has also started with DOGAMAK brand

2020

New cnc machine C, Y B axis, counter mirror features with investments in different sectors

2023

In order to increase the volume of exports abroad, a European office was established in Sofia, Bulgaria

2024

WATCH VIDEO

Short introduction video about our company

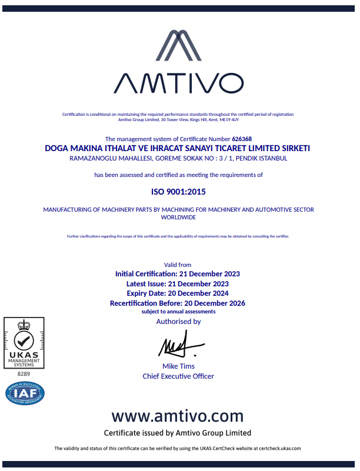

QUALITY CERTIFICATE ISO 9001:2015

Our company, which has ISO 9001 Quality certificate since 2002, fulfils the requirements of quality standards at every stage of production and is extremely determined in this regard. Doğa Makina, which has become a nationwide brand in products such as spare parts for rolling mills, rolling rollers, rolling mills, rings, etc., has many years of experience and experience in this field.

Our Documents

Our Documents

Sustainability

Waste management

Optimise production processes to reduce the amount of waste. Establish appropriate systems for recycling and reuse of waste.

Energy efficiency

Use innovative technologies and equipment to reduce energy consumption. They can carry out improvement works to increase energy efficiency in production processes.

Material utilisation

It is important to prefer sustainable materials and to use resources effectively. The use of recyclable or renewable materials can reduce environmental impact.

Environmental monitoring and reporting

They can carry out regular environmental monitoring and reporting to monitor and assess environmental impacts. This is important to identify areas for improvement and monitor their performance.

Employee training and awareness

It is important to educate employees on sustainability and raise awareness. Employee participation in sustainability practices can increase the success of the company.

Supply chain management

Extend sustainability principles throughout the supply chain. In co-operation with suppliers, they can adopt policies to reduce environmental impacts. This includes areas such as material selection, transport methods and supplier performance.

Occupational Health and Safety Policy

Our occupational health and safety policy aims to keep the safety and health of everyone working in the machining industry at the highest level. This policy aims to minimise the risk of any injury, illness or occupational accident to employees and ensures that the highest level of care is taken in all operations of our company.

Training and Information

All our employees undergo a comprehensive training programme before starting work. This training includes safety protocols, equipment use, emergency procedures and risk recognition.

Equipment and Workplace Safety

Equipment and installations in our workplace are regularly checked and maintained. In addition, necessary measures are taken to ensure that our workers use personal protective equipment (PPE) and this equipment is regularly checked and renewed.

Risk Assessment

Risk analyses are regularly performed to identify and assess potential hazards in machining environments. It helps us determine the measures to be taken to reduce the hazards to which workers are exposed.

Continuous Improvement

Our policy is constantly reviewed and opportunities for improvement are sought. Feedback from employees is taken into account and continuous efforts are made to further improve occupational safety and health standards.