CNC (Computer Numerical Control) turning has revolutionised the modern manufacturing world in terms of precision and efficiency. The advanced features offered by CNC machines have made manufacturing processes more flexible and effective. In this article, especially C Y axis and advantages of the opposite mirror we will focus on.

What is CNC Turning?

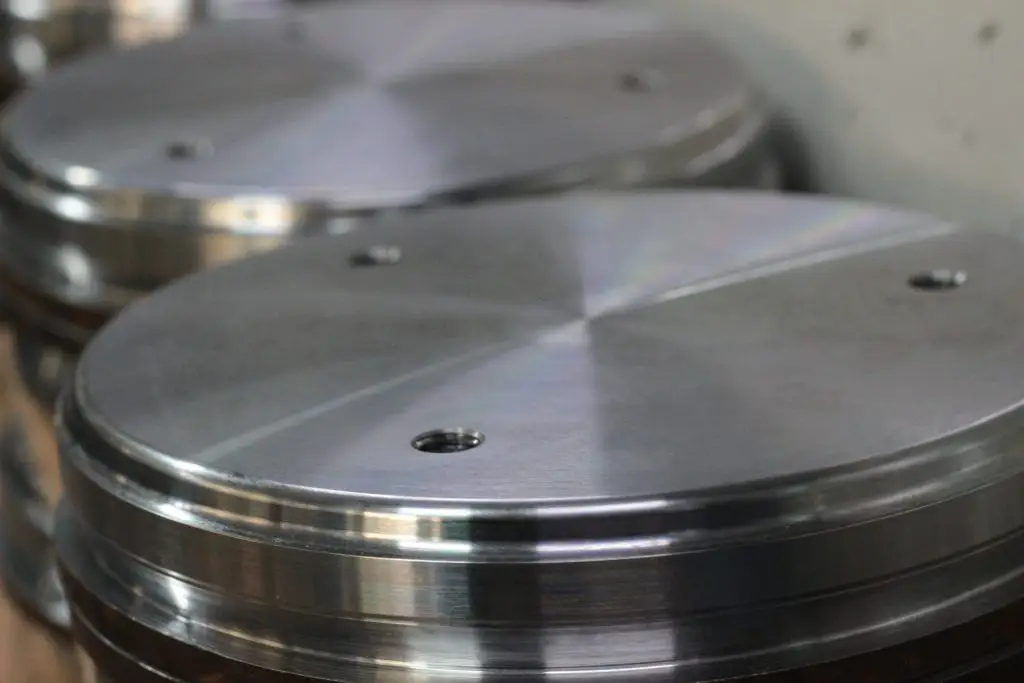

CNC turning is the process of material removal by controlled advancement of cutting tools during the rotational movement of the workpieces. This process is used in the production of parts that require high precision and repeatability. CNC machines are controlled by computer programmes, enabling complex geometries and precise tolerances to be achieved.

What is C Y Axis?

C Y axis is a feature that increases the mobility of the workpiece in CNC turning machines. While standard CNC turning machines usually have X and Z axes, the C axis controls the rotary movement of the workpiece and the Y axis provides the forward and backward movement of the workpiece.

C Advantages of the Y axis:

- Versatile Processing: The C and Y axes make it possible to machine workpieces in more complex shapes. This enables more operations to be performed with a single setting.

- High Sensitivity: Thanks to these axes, more precise operations can be performed at different points on the workpiece. This improves the quality of the final product.

- Reduced Setting Time: C Machines with a Y-axis significantly reduce set-up times as they can perform different operations in a single setting. This shortens production time and increases productivity.

- Flexibility and Efficiency: These features provide great flexibility in machining different types of workpieces. Various operations can be performed on the same machine, which reduces operating costs.

What is a Counter Mirror?

The counter chuck is a tool used on CNC turning machines to support the other end of the workpiece. This feature provides a great advantage, especially when machining long and thin workpieces.

Advantages of the opposite mirror:

- Increased Stability: The counter chuck supports the workpiece at both ends, providing a more stable operation. This reduces vibrations and improves workpiece accuracy.

- Higher Sensitivity: Supporting the workpiece from both ends enables more precise machining. This results in higher quality products.

- Extended Workpiece Dimensions: The use of a counter chuck enables longer workpieces to be machined safely. This extends the range of use of the machine.

- Reduced Error Rate: Supporting the workpiece from both ends minimises errors during machining. This increases the reliability of the production process.

Conclusion

The use of C Y axis and counter chuck in CNC turning machines provides great advantages in production processes. The C Y axis increases machining flexibility and precision, while the counter chuck ensures stability and accuracy of the workpiece. These features are critical for improving quality and maximising productivity in modern manufacturing processes.

CNC turning Follow our blog for more information and stay up to date with the latest technology trends!

Related Keywords:

- CNC turning

- C Y axis

- Counter mirror

- Precision manufacturing

- Production efficiency

- Modern manufacturing technologies