Introduction The Need for Precision Production in Defence Industry

Savunma sanayi, teknoloji ve hassasiyetin buluştuğu en kritik sektörlerden biridir. Bu alanda üretilen parçaların %100 doğrulukla, yüksek tolerans aralıklarında işlenmesi gerekir. Machiningis one of the most important production methods that offers a direct solution to this precision production need.

As Dogamakina, with years of experience machining solutions for the defence industry is developing, high precision CNC machining service We offer.

What is Machining? Why is it so important in the defence industry?

Machiningis a production method that allows the material to be brought to the desired form by removing chips by means of cutting tools. When combined with CNC (Computer Numerical Control) technology, serial and error-free production of parts with complex geometry becomes possible.

Especially for the defence industry:

Barrel parts

Precision fasteners

Missile bodies

Optical system components

Machining is preferred in the production of such parts.

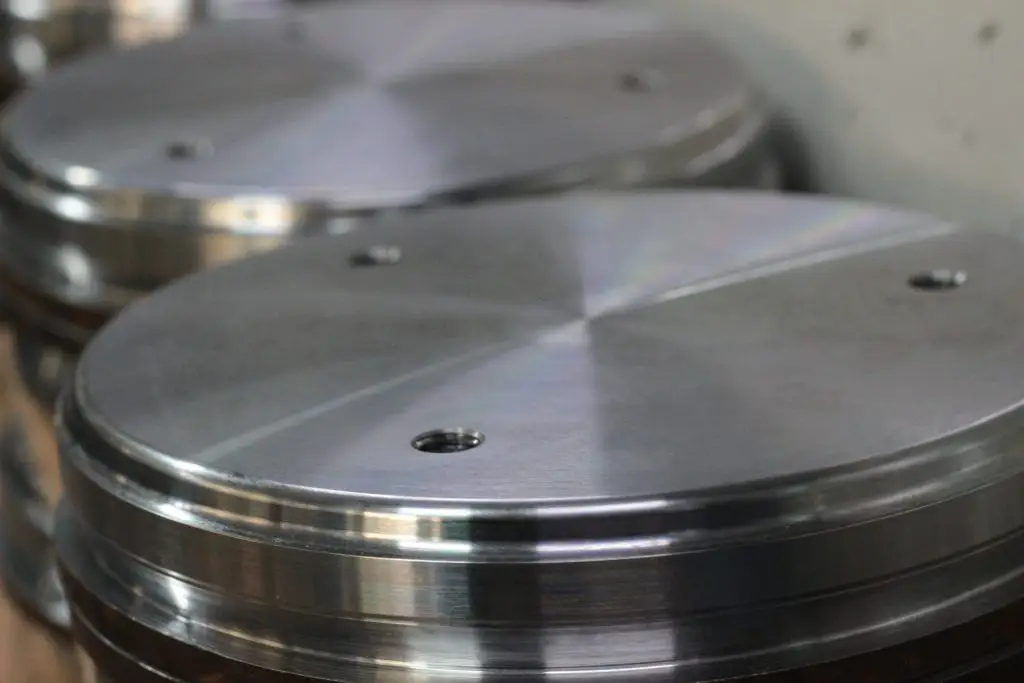

High Quality and Repeatability with CNC Machining

CNC machiningis a digitalised and automation-supported version of machining. Even the smallest micron deviations in the parts used in the defence industry can directly affect the performance of the systems.

As Dogamakina, we offer contract CNC machining servicesprovides the following advantages thanks to our high precision machine tools:

Machining with ±0.01 mm tolerance

3,4 and 5 axis CNC machining capacity

Machining of heat treated alloys

Traceability per piece (lot tracking)

Materials Used and Workability Properties

Parts used in the defence industry are generally manufactured from high strength and special alloy materials. Machining of these materials requires experience and special tool selection.

Commonly used machining materials:

7075-T6 Aluminium (high strength)

Ti-6Al-4V Titanium (balance of lightness and strength)

17-4 PH Stainless Steel (corrosion resistance)

Inconel 718 (heat resistant super alloy)

Dogamakina, specialised for different material groups team routes, cooling techniques and processing strategies improves productivity.

Reverse Engineering & Prototyping Services

Another method frequently used in the defence industry reverse engineering applications. Modelling and reproduction of an existing part with precision scanning devices is of great importance for inventory management and rapid intervention.

Dogamakina:

Digital modelling with 3D scanning

Prototype production

Customised CAD/CAM support

is provided.

Why Dogamakina?

%100 müşteri memnuniyeti

Production in accordance with ISO 9001 quality management systems

Expert engineers in the field of machining and CNC machining

Long years of experience in defence industry projects