PIN BUSHING MANUFACTURING

In the field of precision machining, pin and bushing manufacturingplays a critical role for the reliability and performance of various industrial applications. With 40 years of experience pin and bushing manufacturing we offer high quality products. In this article, we will discuss the details of our manufacturing processes, the materials used and the sectors that rely on our expertise.

High Precision Manufacturing Process

In our plant, we produce pins and bushes with exceptional hardness and precision. Our products are treated to reach a hardness level of 55-65 HRC. After this, they are subjected to rigorous grinding processes to ensure the highest quality surface and performance. We produce pins and bushings ideal for heavy-duty applications using carburised material that increases durability and strength.

bushing manufacturing

bushing manufacturingKey Manufacturing Techniques

- Heat Treatment for Hardness: Our pins and bushings undergo a rigorous heat treatment process to achieve a hardness of 55-65 HRC. This high level of hardness is essential for parts that must withstand significant wear and tear.

- Precision Grinding: After heat treatment, the pins and bushes are subjected to precision grinding operations. This process ensures that the components have a smooth surface and conform to the desired specifications.

- Cementation: We use carburising to increase the surface hardness of the material. This process penetrates the carbon into the surface layer, creating a wear-resistant outer surface, while the interior remains tougher and more flexible.

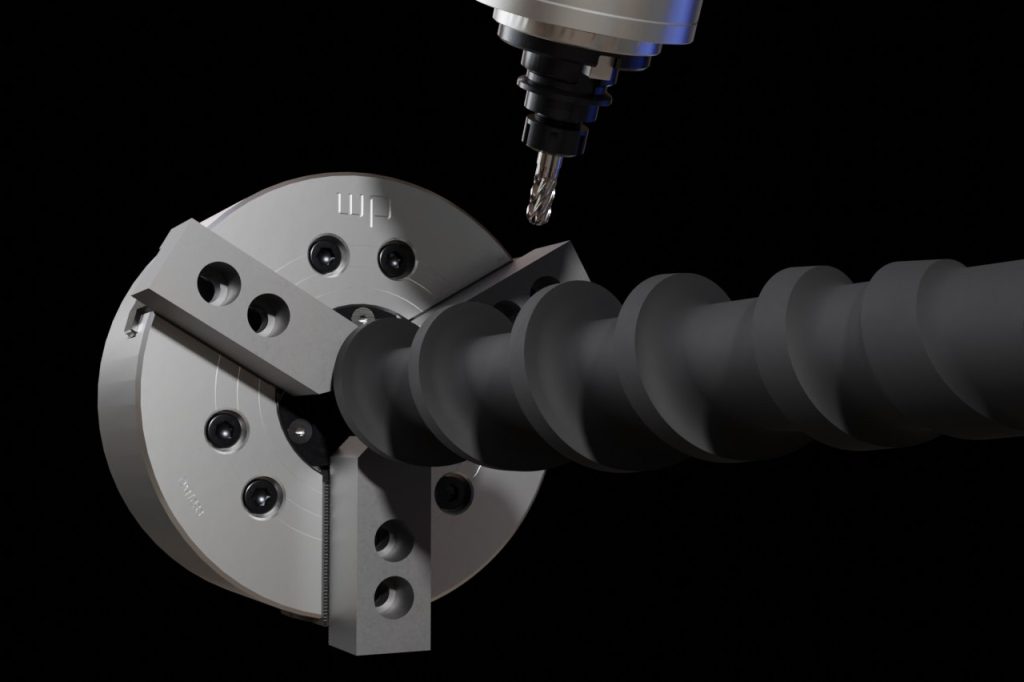

- CNC Machining: Our advanced CNC machines are capable of producing pins and bushings with tolerances as fine as 0.01 mm. This level of precision is required for applications where exact alignment and fit are critical.

Applications in Various Industries

Our pins and bushings are important components in various industries:

- Construction Equipment: In the construction industry, our pins and bushes are used in heavy machinery such as excavators and bulldozers. These parts must withstand extreme conditions and continuous use, which is why our durable and precise products are the ideal choice.

- Automotive Industry: The automotive industry relies on our precision engineered pins and bushings in engines, suspensions and transmission systems. High quality materials and precise manufacturing processes ensure reliability and performance.

- Agriculture Machinery: Agricultural equipment such as tractors and harvesters utilise our robust pins and bushes to ensure efficient and reliable operation under harsh conditions.

- Industrial Machines: Various industrial machines rely on our high-precision components for optimal functionality. Our products help to maintain the efficiency and lifetime of production equipment.

Our Legacy of Excellence

Our company with 40 years of experience, pin and bushing manufacturing is at the forefront in the field. Our commitment to quality and precision has earned the trust of our customers in many industries. We are constantly innovating and improving our processes, delivering components that meet the highest standards of performance and durability.

Conclusion

Pin and bushing manufacturing requires meticulous attention to detail and a commitment to quality. Our expertise in heat treatment, grinding, carburising and CNC machining ensures that our products meet the stringent requirements of various industries. Rely on our 40 years of experience and contact us for components that offer exceptional durability and precision in your projects.