Pin manufacturingis the production of small but important components that play a critical role in mechanical systems. Our company offers the highest level of service in this field with 46 years of experience. In this article, we will discuss in detail the pin manufacturing process, the points to be considered, the materials used, our production quality and the sectors in which pins are used.

Pin Manufacturing?

A pin is a small fastener, usually cylindrical in shape, used in mechanical systems to fasten or align various components together. Pins play a critical role in many industries and are used in a variety of applications. Here is detailed information about what pins are, types and usage areas:Pin manufacturing is a process that requires high precision and experience. The production stages can be summarised as follows:- Design and Prototyping: In the first step, the pin is designed in accordance with customer requirements and industrial standards. The design is verified by prototype production.

- Material Selection: Steel, stainless steel and special alloys are generally used in pin manufacturing. Material selection is determined according to the place where the pins will be used and the expected load carrying capacity.

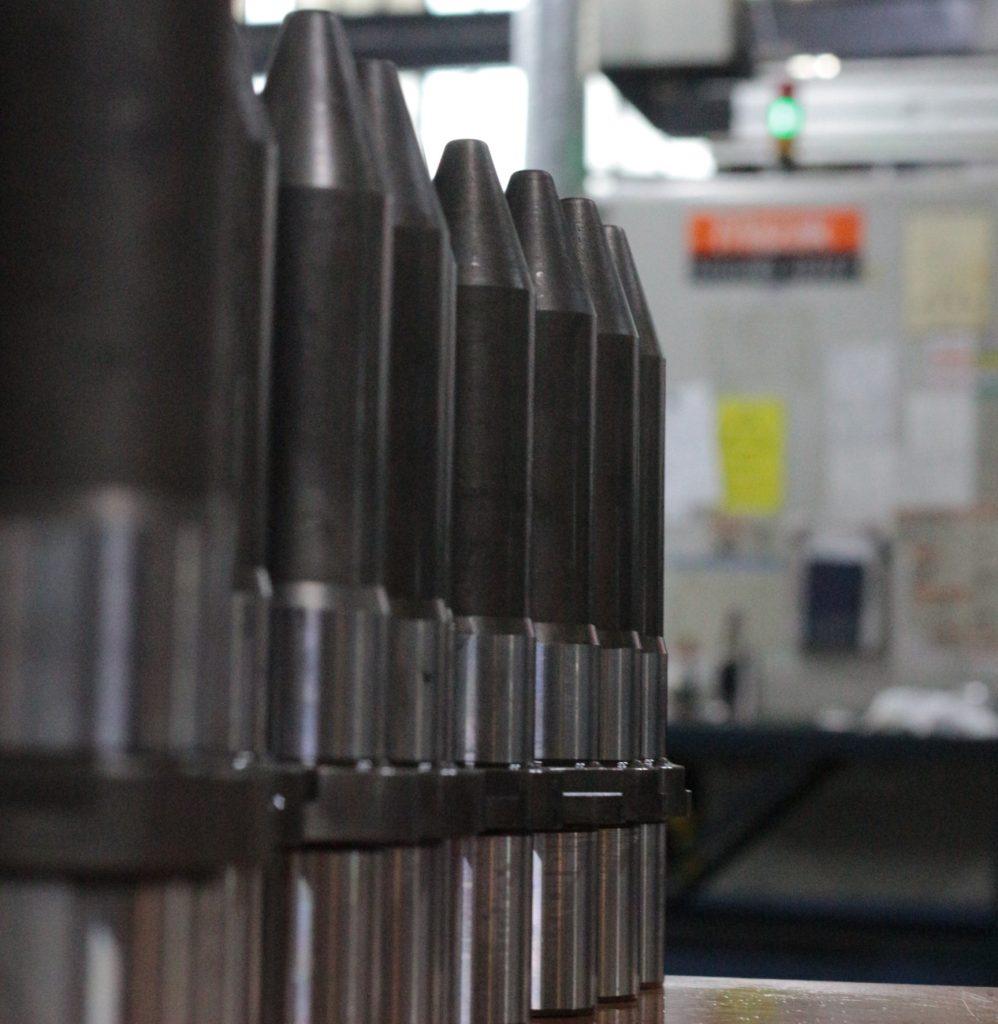

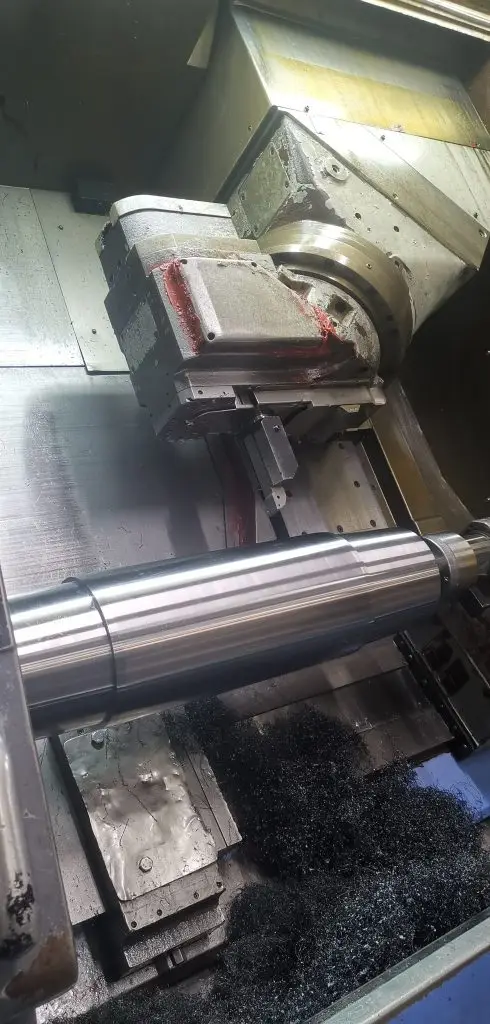

- Production: Pins are manufactured using CNC machines and other precision manufacturing equipment. The highest precision is ensured during the production process.

- Hardening and Grinding: The produced pins are heat treated to reach the required hardness values. Our company can increase the hardness values of the pins up to 60 HRC. Then surface smoothness is achieved by grinding process.

- Quality Control: The pins produced are checked with micrometre precision measuring devices and their conformity to quality standards is verified.

Matters to be Considered in Pin Manufacturing

- Sensitivity: It is very important that the pins are produced in correct dimensions and tolerances. Production and measurement should be made with micrometre precision.

- Material Quality: The quality standards of the materials used directly affect the durability and performance of the pins.

- Heat Treatment and Hardness: Achieving the required hardness values of the pins ensures their long life and durability. Pins with hardness values up to 60 HRC show high performance even under the toughest conditions.

- Surface Quality: Grinding and other surface treatment techniques should ensure that the surface quality of the pins is high. This ensures trouble-free operation of the pins in mechanical systems.

Materials Used and Hardness Values

The most commonly used materials in pin manufacturing are:- Carbon Steels: Provides high durability and hardness. It can reach hardness up to 60 HRC after heat treatment.

- Stainless Steels: Corrosion resistance is high. Especially suitable for use in humid and corrosive environments.

- Special Alloys: High performance materials developed for specific applications.

Areas of Use of Pins and Industries

Pins are used in a wide variety of industries and applications. Here are some important areas of use:- Automotive Sector: Pins are used in vehicle engines, transmissions, suspension systems and other mechanical components. Pins ensure the correct alignment and secure connection of moving parts in these systems.

- Machine Manufacturing: Pins are used in industrial machines, CNC machines, press machines and other production equipment. They play a critical role in ensuring precise movements and connections in these machines.

- Aviation and Space: Pins are used in aircraft engines, landing gear and other aerospace components. The quality of the pins is of vital importance in these applications, which require high durability and precision.

- Electronics and Electricity: Pins are used in electronic devices, circuit boards and electrical panels. In these applications, pins are used to ensure precise connections and electrical contacts.

- Medicine and Medical Equipment: Pins are used in surgical instruments, prostheses and other medical devices. Pins made of sterilisation resistant and biocompatible materials are preferred in this field.

- Furniture and Construction: Pins are used in furniture fasteners and construction equipment. Pins play an important role for durable and secure connections.

Why Should You Prefer Us?

- 46 Years of Experience: Our company is one of the pioneers of the sector with 46 years of experience in pin manufacturing. The knowledge and experience we have gained over these long years enables us to offer the best quality products to our customers.

- High Quality Standards: We always aim for the highest quality standards with our high-tech production facilities and expert staff.

- Customisable Products: We manufacture customisable pins according to customer demands and specifications. We can custom design and manufacture according to your needs.

- Fast and Reliable Delivery: We deliver your orders on time and in full. We keep customer satisfaction at the highest level with meticulous planning in our production and delivery processes.

- Customer Support: We are always at your side with our customer support before and after sales. We answer your technical questions and offer solution-oriented approaches.