DOGA MAKINA - SINCE 1978

CNC MACHINING

Since 1978, we have been a sub-industry to the large industrial enterprises of our country and we have been a successful solution partner as subcontract and mass production, and we continue our production to meet the demands of industrial companies.

CNC MACHINING

46 Years machining experience

Our company, which closely follows new developing technologies, bought its first cnc machine in 1989 and became a pioneer in this sector. Since 2002, it has iso quality certificate and continues to do so.

Cooperation with different customers

Years of experience and continuity

tonnes or more of processed material

Completed machining project

DOGA MAKINA

Machining and CNC Machining Services

Machining Doğa Makina, one of the leading companies in the sector, offers high quality and precision machining solutions. Our long years of experience and advanced technology CNC machining We provide the best service to our customers with our equipment.

CNC Machining

With our modern CNC milling and CNC turning machines, we produce precision and complex parts from various materials. We offer solutions for all your machining needs with our team specialised in metal, plastic and composite materials.

Precision Machining

With our precision machining techniques, we pay attention to even the smallest details and produce customised parts according to customer requirements. Whether prototype or series production, we guarantee high quality in every project.

Metal Processing

With our extensive experience in metal processing and state-of-the-art machinery, we produce parts from aluminium, stainless steel and other metals. We stand out with our solutions for the automotive, aerospace and medical sectors.

Customised Part Production

We provide special part production and design services by offering special solutions to the needs of our customers. We produce with high precision and quality, prioritising customer satisfaction in every project.

Cnc Machining

Processing Services

Cnc Turning

Machining capacity between Ø30-740mm and up to 500mm in length, fast machining with counter chuck and rod drive under Ø60

Cnc Machining

X 1000mm, Y 500mm, Z 500mm milling operations in 2.5 axis, 3 axis, 3 + 1 axis operations...

Cnc Turning Centre

Ø600mm, Z 1200mm and C, Y and B axis counter chuck cnc turning centre works are performed.

Cnc Grinding

Grinding operations are performed on the hardened material on the cnc lathe at a tolerance level of 0.01.

Heat Treatment

The desired material can be treated with 70 HRC hardness, carburising, reclamation, stress relieving, normalisation, etc.

Coating

Different coating processes such as anodising, chrome, zinc, phosphate, copper, Cr3, nickel, black oxide coating, etc...

Sustainability

Committed to Keeping Healthy and Safe

Our CNC machining company works towards meeting the needs of both current and future generations by using natural resources in a balanced way with the principle of sustainability.

Why DOĞA MAKİNA?

With years of experience in machining and CNC machining We have an expert team in the field. We maintain our leading position in the sector by offering the most appropriate solutions to customer demands.

- Experience and Expertise

- On Time Delivery

- Modern Technology

- Quality Control

Your Global Solution Partner

Domestic and International Machining Company

Specialised in machining and CNC machining, Doğa Makina provides high quality services to its domestic and international customers. With our large production capacity and our understanding of quality in international standards, we are signing many projects throughout Turkey and around the world.

- International Experience: With our extensive experience in the global market, we offer solutions for all your machining needs.

- Quality and Trust: We produce at the highest quality standards for both domestic and foreign customers.

- On Time Delivery: We keep customer satisfaction at the highest level by guaranteeing on-time delivery for each project.

Contact us for more information and to get a quote for your projects. We are here to provide the best service to all our customers at home and abroad.

Latest News

We add value to our customers

46 years of experience in machining services

Sensitive

Production

Productivity

Cost

Technological

Progress

Sectors

Sectors we work with

Machine

Sector

Iron Steel

Sector

Automotive

Sector

Railway

Sector

Our Advantages

Our Services

Flawless engineering

Expert Staff

Our expert staff in machining, with its experience and expertise in the sector, performs your work in the highest quality and reliably.

Just in Time Production

Just in Time Production

We have a first-class staff in machining that ensures just-in-time production. We guarantee on-time and complete delivery of your jobs

Traceability

Traceability

We provide traceability in the machining process. You can follow your production process transparently at every stage.

C - Y - B axis

Multi-axis Machine Park

Our multi-axis machine park offers the latest technology for the precise production of complex parts.

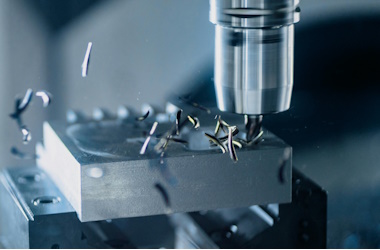

Images from Machining

Current photo and video images from our factory

Request an Offer

Do you have parts you want to manufacture? Send it now and get your price offer.

For more information

Frequently Asked Questions

Commonly used solidworks design file formats for machining include formats such as STEP, IGES, STL and DXF.

In the manufacturing process, costs can be optimised depending on factors such as machine selection, material selection, machining time, labour costs and energy consumption.

The main machines commonly used in machining include CNC milling machines, CNC turning machines, CNC turning centre, drilling machines and grinding machines.

Sustainability in the manufacturing process can be achieved by focussing on factors such as waste management, energy efficiency and the use of renewable resources. This is important to reduce environmental impacts and ensure more efficient use of resources.

In machining, tolerances are ensured by the precision of cutting tools and the accuracy of machine settings. Surface quality is determined by the suitability of machining parameters and cutting tools.

Workpieces can usually be manufactured from a variety of desired materials such as steel, metal alloys, aluminium, plastics, composite materials and ceramics.

We guarantee every technical data from our customers by signing a confidentiality agreement if requested.

In our programming department, solidworks cad drawing, edgecam and hypermill programs are produced special nc post for each machine within the scope of glass programming.

Quality control is performed with measuring instruments (callipers, micrometers, CMMs) and visual inspections. Quality control is important to verify that workpieces conform to tolerances. Final inspection reports are provided with the shipment.

Tolerances are ensured by precise cutting tools, accurate machine settings and good programming. Regular calibration and maintenance also help to maintain tolerances. Our experience is also an important factor.

Safety at work is ensured by the use of machine protective equipment, personnel training, proper work procedures and the use of personal protective equipment (PPE). Safety features such as emergency stop buttons and safety sensors are also important. Our factory adheres to the laws on occupational safety.