Introduction

Since the industrial revolution, machining has been the backbone of modern production processes. Today, with the increasing importance of the concept of sustainability, environmentally friendly and sustainable practices are increasing in the machining sector. In this article, we will discuss the importance of machining in terms of sustainability and the innovations made in this field.

What is Machining?

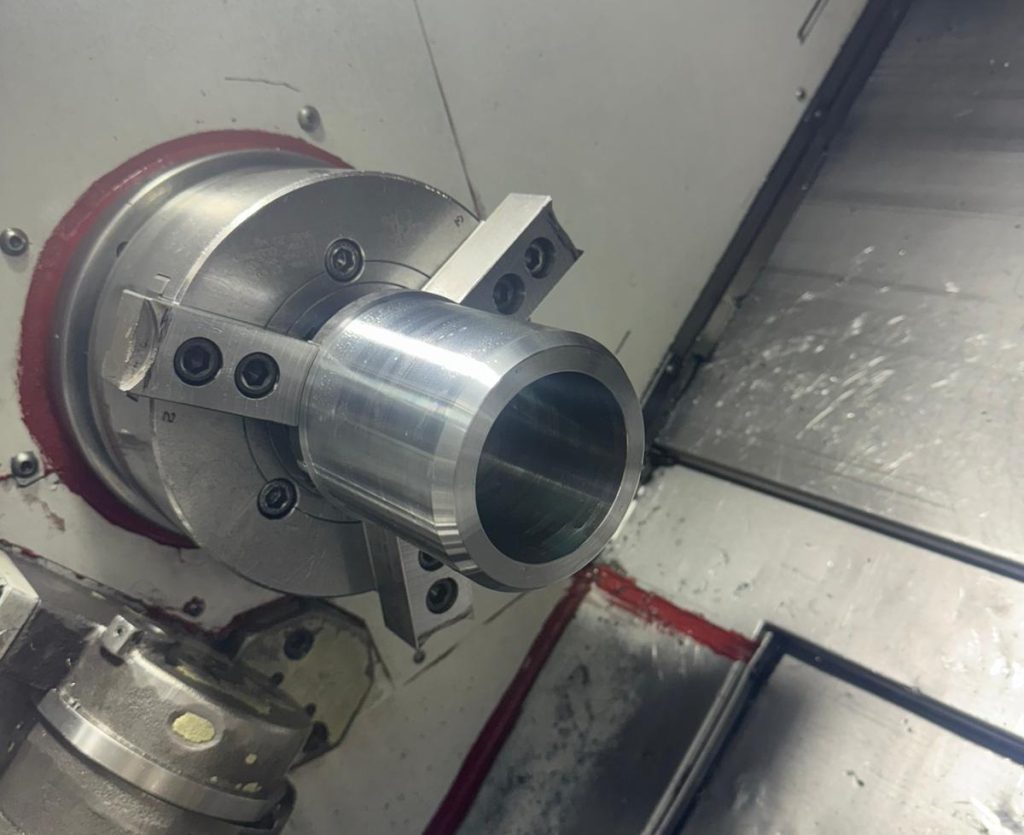

Machining is the process of cutting the excess material into small pieces called chips during the shaping of metal, plastic and other materials. This process, which is carried out using various machines such as CNC machines, milling machines, lathes, provides high precision and repeatability.

Why is Sustainability Important?

Sustainability focuses on goals such as preserving natural resources, increasing energy efficiency and minimising waste. Sustainability in the manufacturing sector is of great importance in terms of both reducing environmental impacts and reducing operating costs. Therefore, adopting sustainable practices in machining processes provides great benefits to both the environment and businesses in the long term.

Sustainable Applications in Machining

- Material Selection and Use: The use of recyclable and environmentally friendly materials reduces the environmental impact of machining. Furthermore, optimisation techniques can be used to minimise material waste.

- Energy Efficiency: Increasing the energy efficiency of CNC machines and other machining equipment reduces both energy consumption and carbon footprint. Energy efficient motors and optimisation software play an important role in this regard.

- Waste Management: Proper management of chips and other waste helps to minimise environmental impacts. Recycling and waste minimisation strategies are critical to achieving sustainability goals.

- Cooling and Lubrication Systems: The use of environmentally friendly cooling and lubrication systems increases the sustainability of machining processes. Water-based or biodegradable coolants reduce the use of environmentally harmful chemicals.

Future Technologies

Sustainability-orientated technologies have an important place in the future of machining. For example, digital twin technology enables production processes to be simulated and optimised in a virtual environment. In this way, energy and material savings can be achieved.

Furthermore, artificial intelligence and machine learning contribute to sustainability goals by improving the efficiency of machining processes. Smart sensors and data analytics monitor the performance of machines, minimising energy consumption and material waste.

Conclusion

Machining is undergoing a significant transformation in line with sustainability principles. Practices such as environmentally friendly materials, energy efficient machines and waste management both reduce environmental impacts and provide economic advantages to businesses. In the future, significant progress will be made in the machining sector as sustainability-oriented technologies become more widespread.

As Doğa Makina, we support sustainable production technologies and are proud to offer environmentally friendly solutions. We will continue to work for a more sustainable future.